In a cloud-centric digital economy, businesses prefer operators who have streamlined and automated processes that keep DCs at optimum condition

As part of the global infrastructure that drives the digital economy, data centers (DCs) are the vital facilities where the cloud “lives”. While DCs have been around since at least the dawn of the computing age, their importance has grown exponentially with digitalization, the growth of the internet economy, and e-commerce.

The digital economy has become a major contributor to GDP (Gross Domestic Product) growth across nations and this is fuelling the demand for cloud-based services as more data is stored in DCs for security and ease of access.

Due to this, DC downtime can have a devastating consequence for both service providers and end-users. It is, therefore, imperative for DC operators, like Princeton Digital Group (PDG), to protect their premises from both external and internal environmental influences that could impact DC efficiency and operations. Key considerations include good infrastructure, reliable access to power distribution, optimal DC environment, and connectivity to primary data routes.

Indonesia is a good example of how digital transformation is changing the economy. The country’s e-commerce market is the largest and fastest-growing in the ASEAN region. Worth US$27 billion in 2018 in GMV (Gross Merchandise Value), it is expected to reach US$100 billion by 2025, growing with a compound annual growth rate (CAGR) of 49 percent. This translates to US$4 out of every US$10 spent on e-commerce in the ASEAN region [1].

In order to enable this growth in Indonesia and other countries, the cloud needs to be easily accessible to both consumers and businesses as it is the virtual platform on which e-commerce transactions take place. This puts the onus on DC operators to ensure that operations run smoothly 24/7.

Data center colocation operators, like PDG, provide customers service level agreements (SLAs) that require a 99.999 percent (five nines) uptime in a year. This translates into a maximum permissible annual data center downtime of just 5 minutes. In order to achieve this, PDG ensures that its data centers have trained staff on hand, at all times and throughout the year, to troubleshoot problems either remotely or on site, if the need arises.

Always on

As a major DC operator in Indonesia, PDG strives to ensure that its customers, many of them hyperscalers with global dominance in the cloud computing space, have an always-on availability to their data through its DCs.

PDG follows standard business process metrics that are rooted in operational excellence (OE) best practices. Optimization is at the center of operations right from the design phase to maintenance and improvement. This allows PDG to quantifiably measure every aspect of the operations and improve these based on these measurements. This is a continuous process that helps to improve systems and processes and make sure all operational aspects are under control.

PDG has a strong commitment to build and operate based on a standard business process to maintain excellent service reliability for all customers. This applies to both Greenfield as well as Brownfield projects. The endeavour is to ensure that the business processes are simple and easy to control.

While it is possible to incorporate new methodologies and technologies in existing DCs, it is best to build optimization into the design and construction phase itself. One of the key considerations that need to be taken into account is built-in flexibility in the design to ensure that future growth and improvement are possible.

PDG ensures that its business processes are agile enough to adopt future growth and scalability with stringent security for all current and future customers. The company has implemented automation at all levels to minimize human error and at the same time have a more accurate and faster response time to fluctuating operations dynamics.

Energy-intensive

DCs are energy-intensive facilities and it is estimated that DCs around the world together consume more than one percent of the world’s total electricity production [2]. This energy is transformed into heat and this needs to be rapidly diverted from the sensitive equipment inside a DC.

Maintaining a correct operating environment, with ideal temperature and humidity is vital for the efficient running of DCs. Cooling and air conditioning are some of the most important processes in a DC, which account for a larger portion of the total energy use than the actual computer equipment itself.

PDG uses technologies that allow engineers to optimize the temperature in the data hall, while at the same time reduce the Power Usage Effectiveness (PUE) benchmark. Benchmarking a DCs energy efficiency is a key first step towards reducing power consumption and related energy costs. In this, PUE is a widely accepted standard benchmark used by the industry to help determine energy efficiency in DCs [3]. The lower the PUE reading is the greater the energy efficiency.

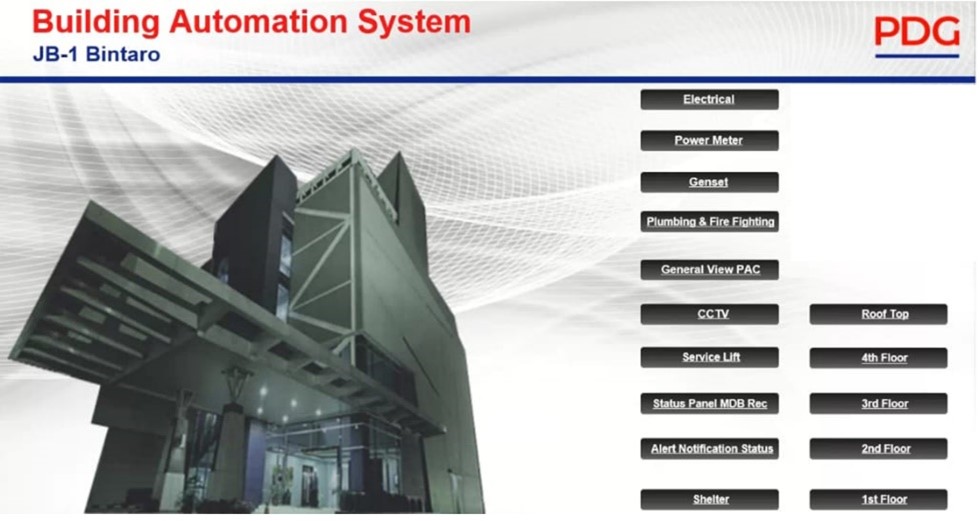

PDG’s BAS (Building Automation System) system provides visibility to the PUE at its five DCs in Indonesia in real time. The BAS dashboard has the ability to monitor the PUE of all the five DCs in real time and also has the granularity to be able to monitor electricity usage per rack.

In order to avoid human error, PDG maximizes the use of automation to monitor temperature, humidity and power usage. Automation has allowed PDG to achieve 100 per cent of its SLA in respect to power, temperature and humidity in all five DC situated in different locations in Indonesia.

Understanding markets

As a major DC operator in Asia, PDG understands the markets in which it has facilities due to the depth of the local team’s experience and knowledge. It follows a collaborative approach during the design and build phase in which its engineers work with partners in the supply chain (technology vendors) and engineering and project partners (design/build) in order to build out the most modern and efficient DCs which are benchmarked with the world’s best.

Business process automation plays a major role on how PDG is able to operate efficiently. Resource utilization is important with electricity and water being the two most significant resources in the context of DC operations.

PDG has a central engineering team which has in-depth knowledge of global best practices, that collaborates with technology partners to develop tools and systems for use in its facilities. This global knowledge complements the local regional engineering and operations team’s expertise which includes an understanding of the local ecosystem.

This enables PDG to get the best of both global and local practices. As a result, customers receive consistent experience from market to market since PDG’s operational processes are consistent across geographies.

For some of its largest customers, PDG mirrors their operational practices, thereby creating a bespoke solution that is an extension of their team. PDG then standardizes this approach and expands the customer relationship into new markets.

About PDG

Princeton Digital Group (PDG) is a leading investor, developer and operator of Internet infrastructure. Headquartered in Singapore with presence and operations in China, Singapore, India, Indonesia, and Japan, its portfolio of data centers powers the expansion of hyperscalers and enterprises in the fastest-growing digital economies across Asia.